Vacuum Insulated Phase separator

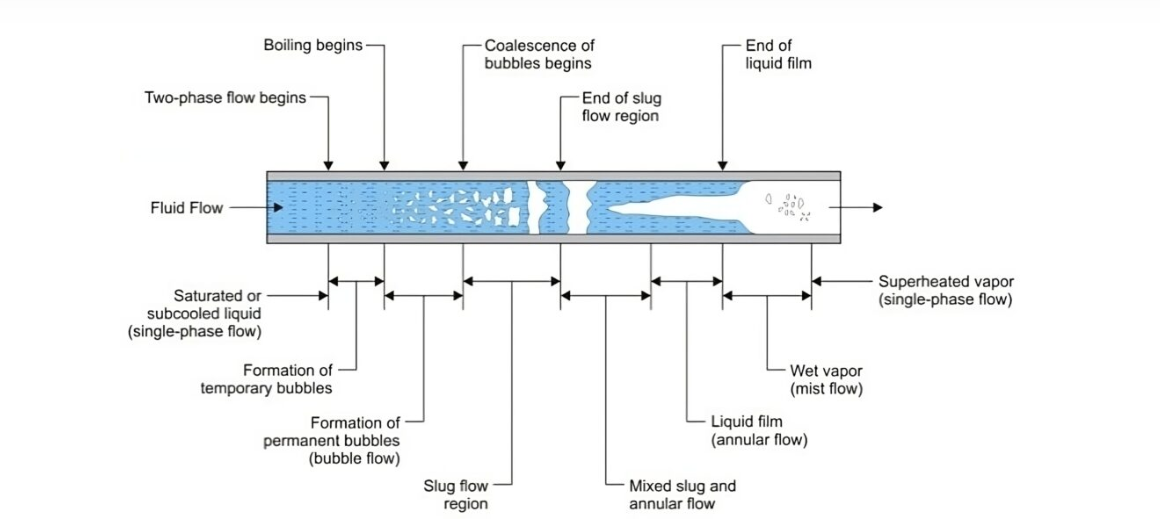

Degasser The degasser removes gas by slowing down the liquid flow velocity, ensuring that.The liquid nitrogen is stored in a bulk storage tank at various saturation pressure, usually between 5 to 10 bars (80 to 150psi). The saturated liquid is drawn from tank and transferred via vacuum jacketed pipelines to the point of use (POU) at the production floor. Liquid nitrogen travels through the pipelines will picks up energy incrementally due of presence of heat leaks, surface friction and turbulence at bends. Depending on the amount of the energy absorbed, the liquid enthalpy increases and vapor is formed creating gas bubbles in liquid stream, resulting in 2-phase flow conditions as shown in diagram below. Appropriate conditioning equipment are used to remove the vapor from 2-phase liquid to provide users with single phase liquid supply.

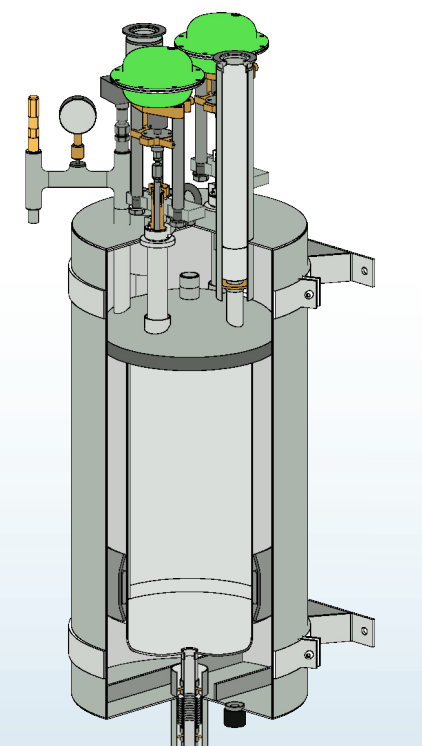

Product Description

Vacuum Insulated Phase separator

General

Theis Vacuum Insulated Phase separator used to separate gaseous nitrogen from liquid nitrogen. Beside this

main function the phase separator has two extra functions in a LN2 system. The phase separator has

the ability to reduce the pressure to a free adjustable and stable application pressure. The flash off

that occurs due to the pressure drop, will be vented by the phase separator. The phase separator has

an internal storage capacity which allows to create a buffer in case of fluctuating consumptions.

Characteristics

A Vacuum Insulated Phase separator has a very low heat in-leak because of the super insulation by high static

vacuum level and radiation shielding. By using a phase separator a high quality of liquid medium in

the vacuum insulated pipeline (VIP) is always available

Technical details standard design

Positioning:Indoor / outdoor, IP65

Orientation:Vertical vessel

Volume inner vessel:40 litres liquid

Connection:Vacuum Insulated Phase separator

Output volume:1600 L/h standard

Filling:Open / Close valve

Inlet pressure:Maximum 12 bar

Outlet pressure:From pressure less until 12 bar(g)

Supply voltage:230VAC or 24V DC/AC

Level sensor:Capacitive (DeMaCo design)

Air supply for valve(s):4-5 bar(g)

Pressure indication:Pressure gauge

Safety precaution:Pressure relief valve to prevent over pressure

Description

Liquefied gasses which are normally stored in a bulk tank will be transferred to the application bypipelines. The liquefied gas in a transfer line consist of a liquid and gaseous phase caussed by heatin-leak and pressure drop. The phase separators of Vacuum Insulated Phase separator are being designed to separate the two phases in order to supply the highest level of purity of liquid gas at the application.The Vacuum Insulated Phase separator consists of a vacuum insulated vessel with a level sensor. The level sensor is connected to a separate control and read-out unit, which controls the inlet valve depending onthe level of liquid nitrogen in the phase separator. The display of the unit shows the level of nitrogen inside the phase separator. Each phase separator has one inlet and one or more outlets depending on the type of application. For the surface mounting the phase separator is provided with clamps.Vacuum Insulated Phase separator has a standard phase separator with a short delivery time.