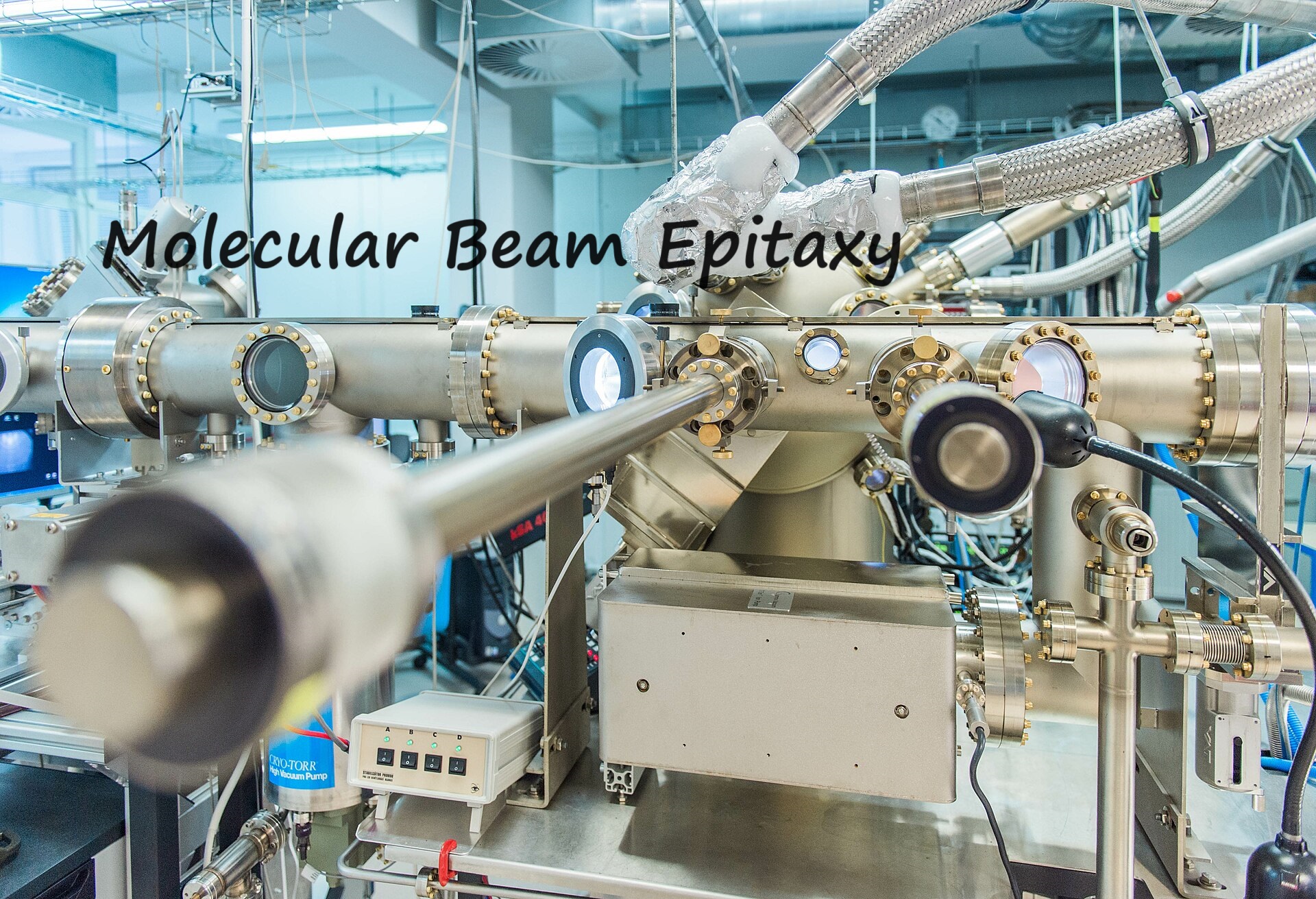

Molecular Beam Epitaxy or MBE is an Ultra-High-Vacuum (UHV)-based technique for producing high quality epitaxial structures with monolayer control.

Since its introduction in the 1970s as a tool for growing high-purity semiconductor films, MBE has evolved into one of the most widely used techniques for producing epitaxial layers of metals, insulators, and superconductors as well. Today MBE is an indispensable tool in compound semiconductor industry, both at research and production level.

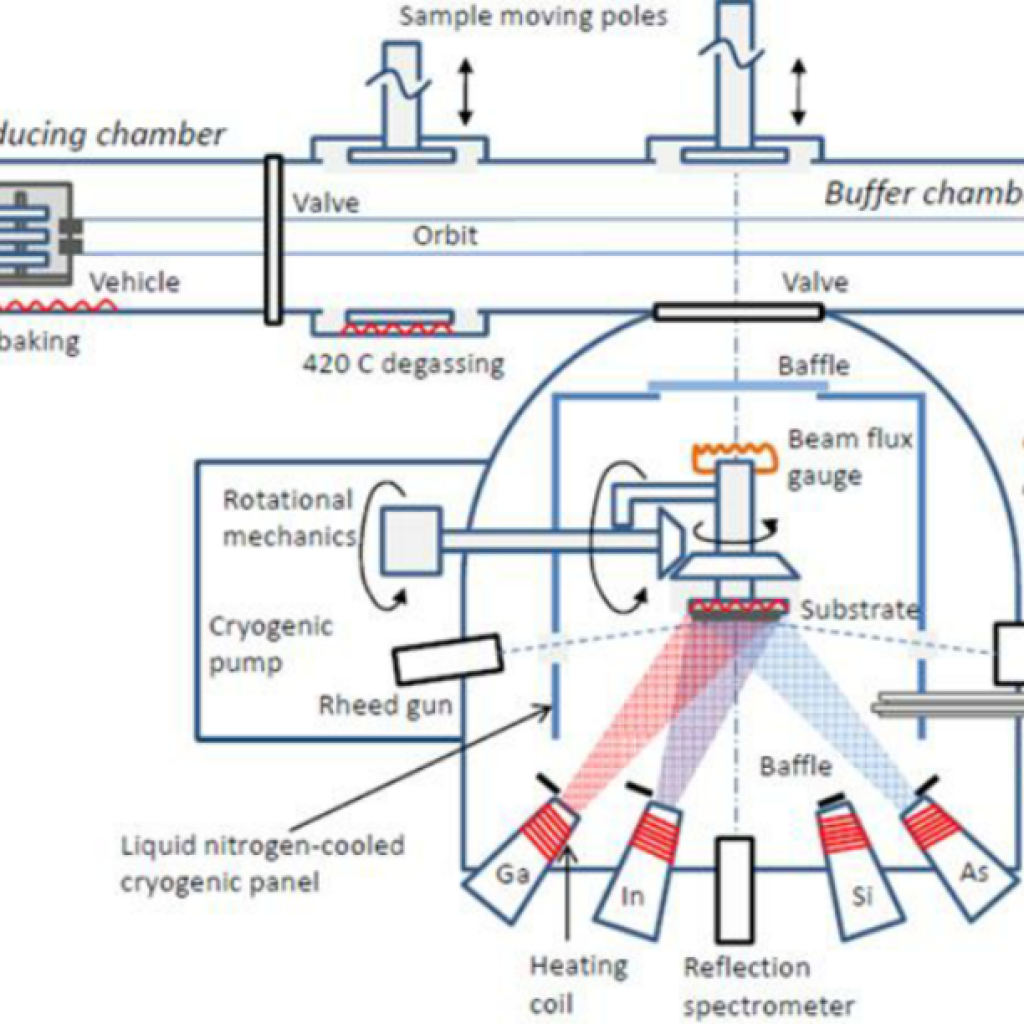

Liquid N2 is very important component for successful operation of MBE. MBE system relies on Liquid N2 cryopanels, built internally around both the main chamber wall and the source flange. Since MBE is a cold wall technique, cryopanels are used to prevent re-evaporation of molecules from parts other than the hot effusion cells.

Besides, they provide thermal isolation among the different cells, as well as additional pumping of the residual gas. Low vapor pressure liquid N2 supply within cryopanels during wafer growing process is paramount to ensure impurities partial pressure are maintain consistently below 10e-12 Torr.

CSM-Cryogenic, a Malaysian based company has developed a very advanced closed loop liquid nitrogen circulation system for Molecular Beam Epitaxy MBE wafer growing process.

Close loop LN2 circulation system

Terbo design LN2 close loop circulation system for many MBE system in the world, such as Riber, DCA and Veeco. It has been widely use in many customers for compound semiconductor device development such as infra-red, optical communication and many others. Our system is available in static vacuum or dynamic vacuum insulation. A complete close loop system consist of phase separator with multiple outlets, triax hoses, modular fittings and vacuum jacketed valve for liquid nitrogen flow control and isolation.

Terbo closed loop LN2 system for MBE is maintained at atmospheric pressure at all time. The controller allow the phase separator to self-regulate the LN2 supply flow rate to MBE in a close loop manner, keeping cryopanel always filled full with liquid nitrogen at different operating conditions.

Terbo close loop LN2 system allows the following benefits:

- LN2 saving up to 30%

- Efficient cryopanel cooling to -196 deg oC

- Ease of LN2 operation – self regulating LN2 flow rate according thermal load at various stages of MBE system operation

- No dewar handling

- Safety